How bigger farms leads to more focus on feed data

- NutriOpt

- Dairy

Insights from Thorsten Steidle, account manager NutriOpt at Trouw Nutrition Germany.

In Germany, dairy farms are getting bigger. This consolidation also spurs the demand to better fine-tune rations and control feed quality. The NutriOpt On-site Adviser is a perfect tool to help farmers with these challenges, explains Thorsten Steidle from Trouw Nutrition Germany.

Germany is known as the biggest dairy producer in the European Union but has undergone rapid and far-reaching structural changes in the past decades. Over the years, Germany went through a strong consolidation process in which the number of farms decreased considerably, the remaining farms got bigger and total milk production increased due to an intensification of milk production per cow. Alongside this consolidation, German dairy farmers have been confronted with the rise in production costs and farm sustainability programs in their country.

When growing your own feed ingredients, it is vital to know the quality and components. This is where the NutriOpt On-site Adviser can be of great value to dairy farmers, also because it is a very simple piece of technology to use.

Increase in technology use

According to Thorsten Steidle, account manager NutriOpt at Trouw Nutrition Germany, the consolidation has spurred the technology revolution. “We see an increasing demand among dairy farmers to use more decision support tools to be able to run a large farm that is sustainable, profitable and efficient at the same time. Farms are getting bigger and we see that these professional farms have a high adoption rate for technologies to increase farm efficiency and to reduce costs. The interest in new digital technologies is therefore growing. We not only see that in the increase in milking robots sold in Germany but we also see a growing interest in the digital tools and services we offer at Trouw Nutrition under the name NutriOpt”, Steidle explains.

What’s in my silage?

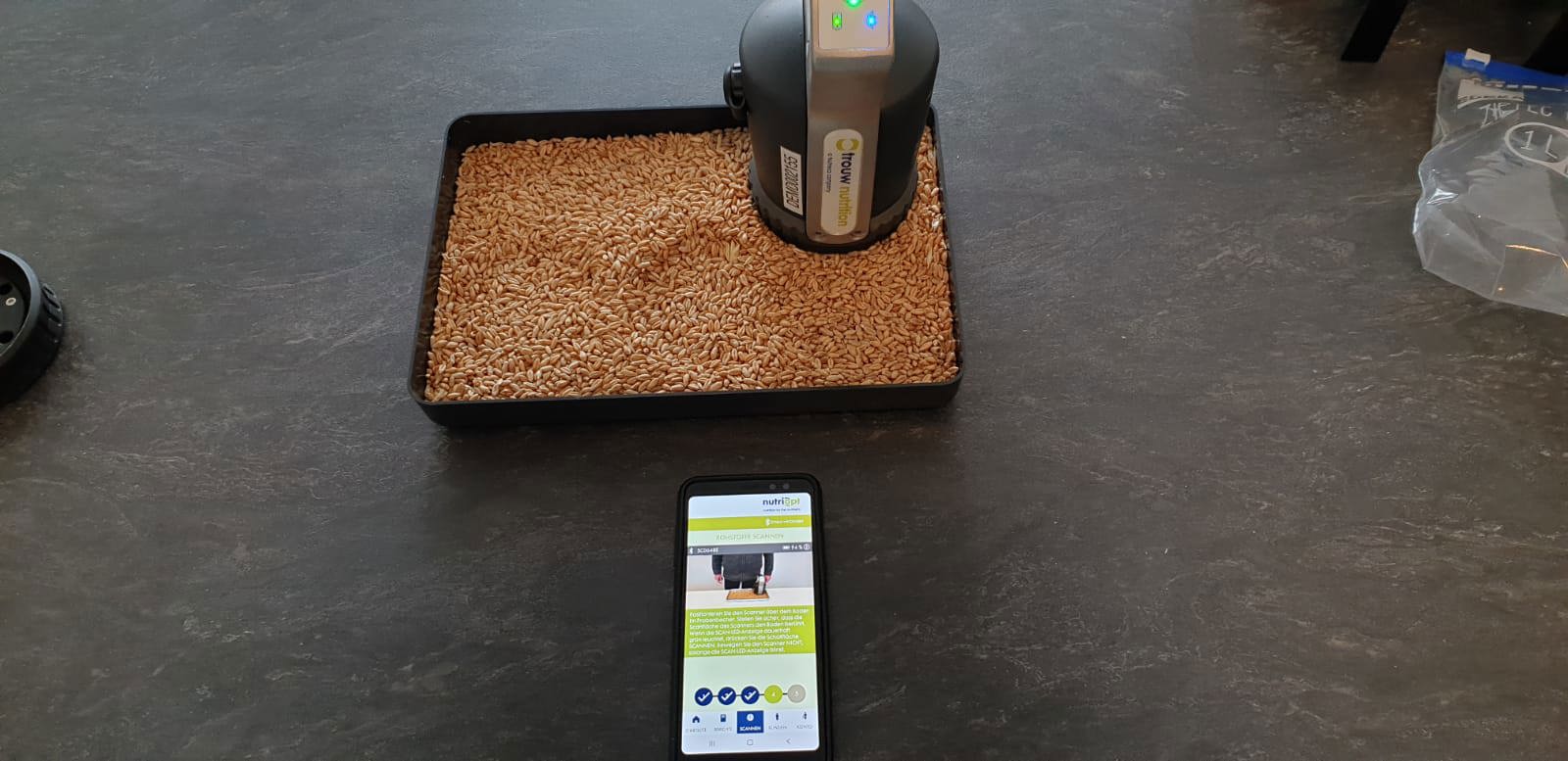

A great example is the introduction of the NutriOpt On-site Adviser on dairy farms in Germany. The NutriOpt On-site Adviser offers real-time analysis by using a Near Infrared spectrometer (NIR sensor) in the form of a hand-held scanning device. After scanning the samples, the hand-held scanner sends all data to the mobile application, which creates a nutritional report of the scanned raw material, using the NutriOpt calibration lines and its nutritional database. “A balanced feed ration is key to reach a higher milk production per cow. Especially on larger dairies we see the interest and need growing to know the feed quality and nutritional values even better. With the NutriOpt On-site Adviser, farmers can do the feed testing themselves in a quick and accurate way. They don’t have to send the samples to the lab anymore, which saves time and money”, Steidle addresses.

The NutriOpt On-site Adviser is the first step of further digitalisation of farms. We believe that this is a great way to get used to sampling and working with the feed data and learn how data can help in making better decisions.

Better control over harvest

In the meantime, Trouw Nutrition Germany has already equipped a number of dairy farms across Germany with the NutriOpt On-site Adviser. “All of these farms, ranging from 100 cows in the South of Germany to even a 1,500 cow dairy in the East, have started to use the scanner a few months ago because they want more information on the quality of their raw materials, silages and complete feed. In addition, farmers want to have a good overview and reporting of the tested feed, so that new employees can easily see what has been fed to the cows in the past and when the ration was adjusted”, Steidle explains. Some German farmers produce compound feed from their own raw materials such as grain and barley. Steidle: “Especially in Southern German, where the relatively smaller dairies are located, a common practice is that farmers grow a number of feed crops and have it turned into compound feed at small, local feed mills. In the Eastern part of the country, home to large farms, farmers also grow a range of raw materials themselves. In turn they have a contract to get compound feed year round. In the Northern part, farmers usually buy the compound feed from suppliers. When growing your own feed ingredients, it is vital to know the quality and components. This is where the NutriOpt On-site Adviser can be of great value to dairy farmers, also because it is a very simple piece of technology to use. And now that we have the ability to test compound feed samples as well with the scanner, farmers can also scan the compound feed, whether or not based on their own feed ingredients. We notice that farmers scan their feed on average once per week. And this is more than they did before when they had to send the samples to an external lab”.

We not only see that in the increase in milking robots sold in Germany but we also see a growing interest in the digital tools and services we offer at Trouw Nutrition under the name NutriOpt.

Making better decisions

The current users of the NutriOpt On-site Adviser are very happy with the results and Steidle projects that the adoption of this technology will further grow in the coming years. “By providing these technologies, the associated services and the ability to connect and integrate the feed data with other data sources on the farm (milk data for example), we want to full-service the farmers to help them optimise feed formulation and overall farm profitability. The NutriOpt On-site Adviser is the first step of further digitalisation of farms. We believe that this is a great way to get used to sampling and working with the feed data and learn how data can help in making better decisions''. But farmers are not the only group to profit from savvy technologies like the NutriOpt On-site Adviser. “Also feed mills, veterinarians and feed consultants are constantly looking for ways to improve diets, prevent nutrient losses and reduce feed costs and are perfect candidates for products like the NutriOpt On-site Adviser. This month, a swine veterinarian will start using it to help decide if certain health issues are feed related. I am excited to hear his experiences in the coming months'', Steidle concludes.